printed circuit board assembly companies compare to traditional PCBs

Printed circuit board assembly (PCBA) companies play a vital role in the electronics industry, providing essential components for a wide range of electronic devices. One aspect that distinguishes PCBA companies from traditional printed circuit boards (PCBs) is the inclusion of electronic components in the assembly process. This addition of components, such as integrated circuits, resistors, capacitors, and connectors, can significantly impact the weight of the final assembly.

Traditional PCBs typically consist of a substrate material, such as fiberglass or epoxy resin, with copper traces etched onto the surface to create electrical pathways. These bare PCBs are relatively lightweight compared to PCB assemblies, as they contain only the substrate and copper layers. The absence of additional electronic components results in a lower overall weight for traditional PCBs.

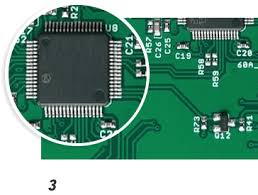

In contrast, PCB assemblies manufactured by printed circuit board assembly companies include not only the bare PCB but also a variety of electronic components soldered onto the surface or inserted into the PCB through-holes. These components add mass and complexity to the assembly, contributing to a higher overall weight compared to traditional PCBs. The weight of a PCB assembly can vary depending on factors such as the number and size of components, the complexity of the design, and the density of the component placement.

How does the weight of printed circuit board assembly companies compare to traditional PCBs?

Furthermore, the type of components used in PCB assemblies can also influence their weight. For example, surface-mount components, which are soldered directly onto the surface of the PCB, tend to be smaller and lighter than through-hole components, which are inserted into holes drilled through the PCB and soldered on both sides. As a result, PCB assemblies with a higher proportion of surface-mount components may have a lower overall weight compared to assemblies with predominantly through-hole components.

Additionally, advancements in component miniaturization and lightweight materials have enabled PCB assembly companies to produce lighter and more compact PCB assemblies without sacrificing functionality or performance. Smaller and thinner components, such as microcontrollers, microprocessors, and passive components, contribute to reducing the overall weight of PCB assemblies while maintaining or even improving their functionality and capabilities.

Moreover, PCB assembly companies often optimize their manufacturing processes to minimize excess material usage and reduce the weight of PCB assemblies. Techniques such as panelization, where multiple PCBs are fabricated on a single larger panel, help maximize material utilization and minimize waste, resulting in lighter and more cost-effective assemblies.

However, it’s important to note that while PCB assemblies may weigh more than traditional bare PCBs due to the added components, this increase in weight is often negligible compared to the overall weight of the electronic device in which the PCB assembly is installed. Factors such as the weight of the enclosure, display, battery, and other components typically contribute more significantly to the total weight of the device.

In conclusion, PCB assembly companies produce PCB assemblies that typically weigh more than traditional bare PCBs due to the inclusion of electronic components. However, advancements in component technology, manufacturing processes, and material utilization help minimize the weight increase while maximizing functionality and performance. Ultimately, the weight of PCB assemblies is just one of many factors considered in the design and manufacturing of electronic devices, with overall performance, reliability, and cost-effectiveness remaining paramount.