printed circuit board manufacturerss be used in aerospace applications

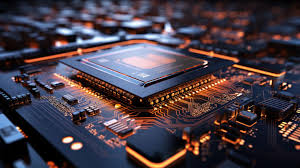

Printed circuit board (PCB) manufacturers have a crucial role to play in the aerospace industry, where reliability, durability, and performance are paramount. Aerospace applications demand electronic systems that can withstand extreme conditions, including temperature variations, high vibrations, and radiation exposure, while maintaining precise functionality and safety standards. PCB manufacturers have risen to the challenge, developing specialized solutions to meet the rigorous requirements of aerospace applications.

One of the key considerations for PCBs in aerospace applications is reliability. Aerospace systems operate in harsh environments, including high altitudes, temperature extremes, and exposure to radiation and electromagnetic interference (EMI). PCB manufacturers employ robust materials, advanced fabrication techniques, and rigorous testing protocols to ensure that aerospace-grade PCBs meet stringent reliability standards and can withstand the rigors of space travel, aviation, and defense applications.

Moreover, printed circuit board manufacturers must adhere to strict quality and certification requirements when producing PCBs for aerospace applications. Certifications such as AS9100, which is specific to the aerospace industry, and IPC standards for PCB design and assembly ensure that PCBs meet the highest levels of quality, performance, and safety. Manufacturers invest in state-of-the-art facilities, equipment, and personnel training to maintain compliance with these standards and deliver reliable, high-quality PCBs for aerospace applications.

Can printed circuit board manufacturerss be used in aerospace applications?

In addition to reliability and quality, PCB manufacturers must consider the unique design and performance requirements of aerospace systems. Aerospace-grade PCBs often feature specialized designs, materials, and construction techniques to meet the stringent demands of space, aviation, and defense applications. For example, multilayer PCBs with controlled impedance, high-density interconnects (HDIs), and thermal management features are commonly used in aerospace systems to optimize performance and reliability in challenging environments.

Furthermore, PCB manufacturers must address concerns related to weight, size, and power consumption when designing PCBs for aerospace applications. Aerospace systems often have strict requirements for size, weight, and power (SWaP), as well as stringent reliability and performance standards. PCB manufacturers employ advanced design and manufacturing techniques, such as miniaturization, lightweight materials, and low-power components, to meet these requirements while ensuring optimal performance and reliability.

Moreover, PCB manufacturers play a critical role in advancing innovation and technology in the aerospace industry. As aerospace systems become increasingly complex and integrated, PCBs serve as the backbone of electronic systems, enabling communication, navigation, control, and monitoring functions. Manufacturers leverage cutting-edge technologies, such as high-speed signaling, embedded components, and advanced materials, to push the boundaries of performance, reliability, and functionality in aerospace applications.

Additionally, PCB manufacturers contribute to the sustainability and environmental stewardship of aerospace systems. As the aerospace industry seeks to reduce its environmental footprint and adopt more sustainable practices, PCB manufacturers are exploring eco-friendly materials, manufacturing processes, and recycling initiatives to minimize waste and pollution. By embracing sustainability as a core value and integrating environmental considerations into their operations, manufacturers can help advance the aerospace industry towards a more sustainable and resilient future.

In conclusion, printed circuit board manufacturers play a crucial role in the aerospace industry, providing reliable, high-quality PCB solutions for space, aviation, and defense applications. Through adherence to stringent quality and certification standards, specialized design and manufacturing techniques, and a commitment to innovation and sustainability, PCB manufacturers enable the advancement of technology and the exploration of new frontiers in aerospace. As aerospace systems continue to evolve and become increasingly complex, PCB manufacturers will remain essential partners in ensuring the reliability, performance, and safety of electronic systems in aerospace applications.