Can an Pcba printed circuit board be customized

Printed circuit boards (PCBs) form the base mechanical foundation for mounting and connecting electronic components. They’re used as a foundation in everything from calculators to high-performance supercomputers. Depending on the complexity of the device, PCBs can be either single- or multilayer. Those with multiple layers contain a conductive pathway that is printed or inscribed on an insulating epoxy glass.

When deciding between a PCB and a pcba, many factors need to be taken into account. Some of the most important include component availability and performance requirements. The latter are especially significant as they can influence the assembly techniques and material selection needed to achieve the desired results.

The most critical factors, however, are the cost and lead time associated with each. Choosing the right option can ensure that your project is completed on time and within budget. This is why it’s vital to partner with a manufacturer that prioritizes efficient manufacturing processes. In addition to prioritizing effective manufacturing processes, a quality printed circuit board pcba manufacturer should offer a comprehensive range of services. This includes testing, a process that can identify electromagnetic issues in advance of production and prevent delays down the line.

Can an Pcba printed circuit board be customized for specific applications?

Another service that is crucial for the successful development of your PCBA is a thorough design review. This process involves a comprehensive assessment of the board’s schematic, including a check for proper connections and a verification of the layout. It also provides an opportunity to address any questions or concerns that may arise.

Once the design has been approved, the next step in the PCBA manufacturing process is schematic capture and synchronization. This process involves importing the component layout files into a design software program and ensuring that the schematic is updated. Once this is complete, the resulting design file can be sent to the fabricator for fabrication.

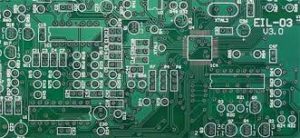

During the fabrication phase, the physical PCB is created based on the design files. This includes etching the copper traces, drilling holes for through-hole components and vias, applying solder mask and silkscreen layers, and more. The resulting fabricated PCB serves as the basis for the final assembled product.

After the PCB is fabricated, it must be prepared for assembly. This process involves soldering or assembling the electronic components to the board, and it can be performed using a variety of assembly methods, including through-hole soldering, surface-mount technology (SMT), or BGA assembly. The resulting assembled products are then ready for final testing and distribution to customers.

While the PCBA is the foundation of any electronic device, it’s important to choose a manufacturer that offers a comprehensive array of services. This way, you can be sure that your finished product is safe and reliable. Ultimately, this can help you deliver a high-quality product to your customers. A quality PCBA can significantly improve the usability and durability of your products. Moreover, it can reduce the amount of time and effort you spend on assembly and testing. Ultimately, it can even save you money on production and warehousing costs.